Templates Community /

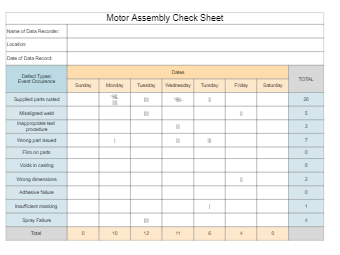

Assembly Check Sheet

Assembly Check Sheet

Captain O Captain

Published on 2021-03-17

The Check sheet is a form used to collect data in real-time at the location where the data is generated. The data or information it captures can be either qualitative or quantitative. A typical check sheet is divided into regions and marks made in different regions have different significance. Data is read by observing the location and number of marks on the sheet. There are primarily five uses for check sheets in quality control, to check the shape of the probability distribution of a process, to quantify defects by type, to quantify defects by location, to quantify defects by cause, and to keep track of the completion of steps in a multistep procedure. A Motor Assembly Check Sheet shows the events occurring on any particular weekday. By creating a defect type as per the weekday, the organization understands what changes they have to make in order to increase the efficiency while maintaining that the cost of repairing should decrease.

Tag

business

Share

Report

3

258

Post