Templates Community /

8M Method Example

8M Method Example

Ashley

Published on 2021-12-16

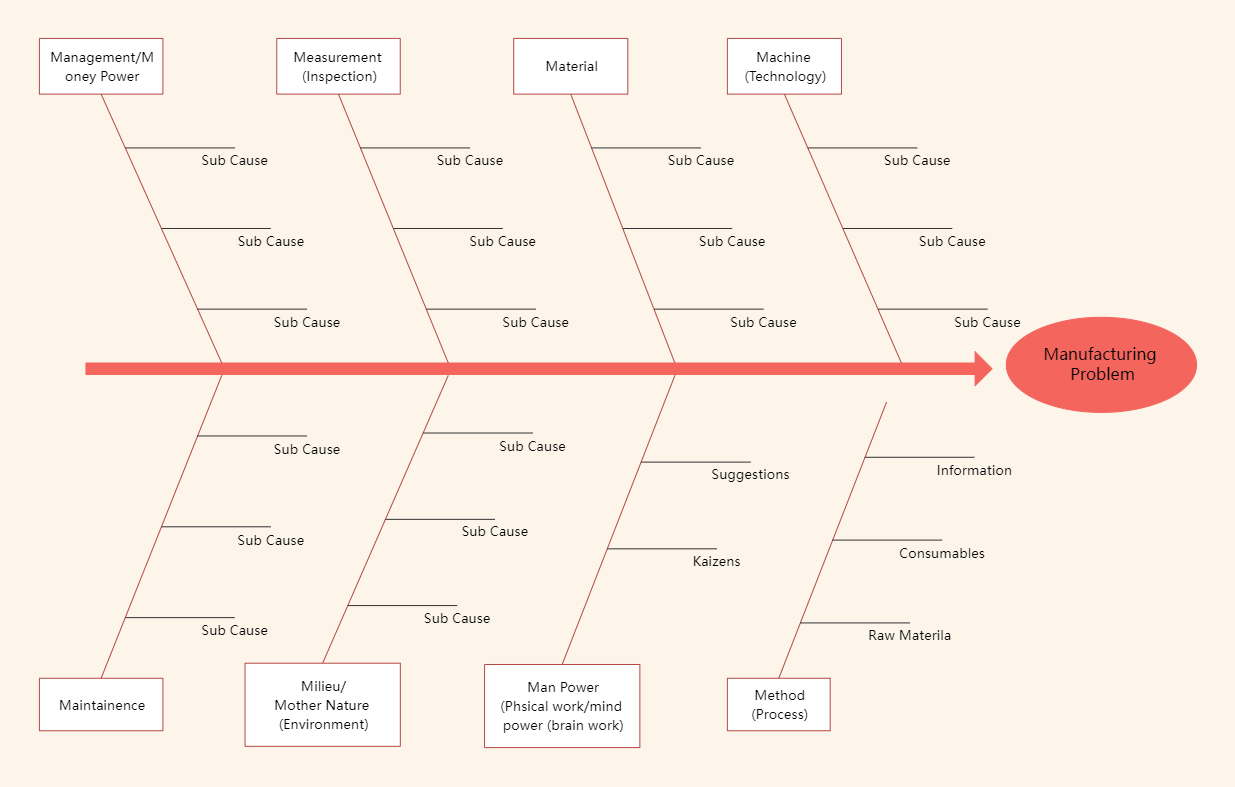

"The 6 M's, for example, are frequently used to categorize causes in the figure...

(1) Machine (technology); (2) Method (process); (3) Material (includes raw materials, consumables, and information. ); (4) Man Power (physical work)/ Mind Power (brain work): Kaizens, Suggestions; (5) Measurement (Inspection); (6) Milieu/Mother Nature (Environment).

Some have expanded the basic 6Ms of the Toyota Production System to include the following, dubbed the 8Ms. This is not, however, a universally accepted fact. Most programs do not address the 8Ms, hence it has been advised that we revert to the tools' roots and keep the instruction basic while understanding the original goal.

(7) Management/Financial Strength; (8) Upkeep." " [Wikipedia: Ishikawa diagram]

The Fishbone Diagram solution from the Management area of ConceptDraw Solution Park includes this 8Ms Ishikawa diagram (manufacturing cause and effect diagram) template.

Tag

fishbone

Share

Report

6

4.1k

Post

Recommended Templates

Loading