Templates Community /

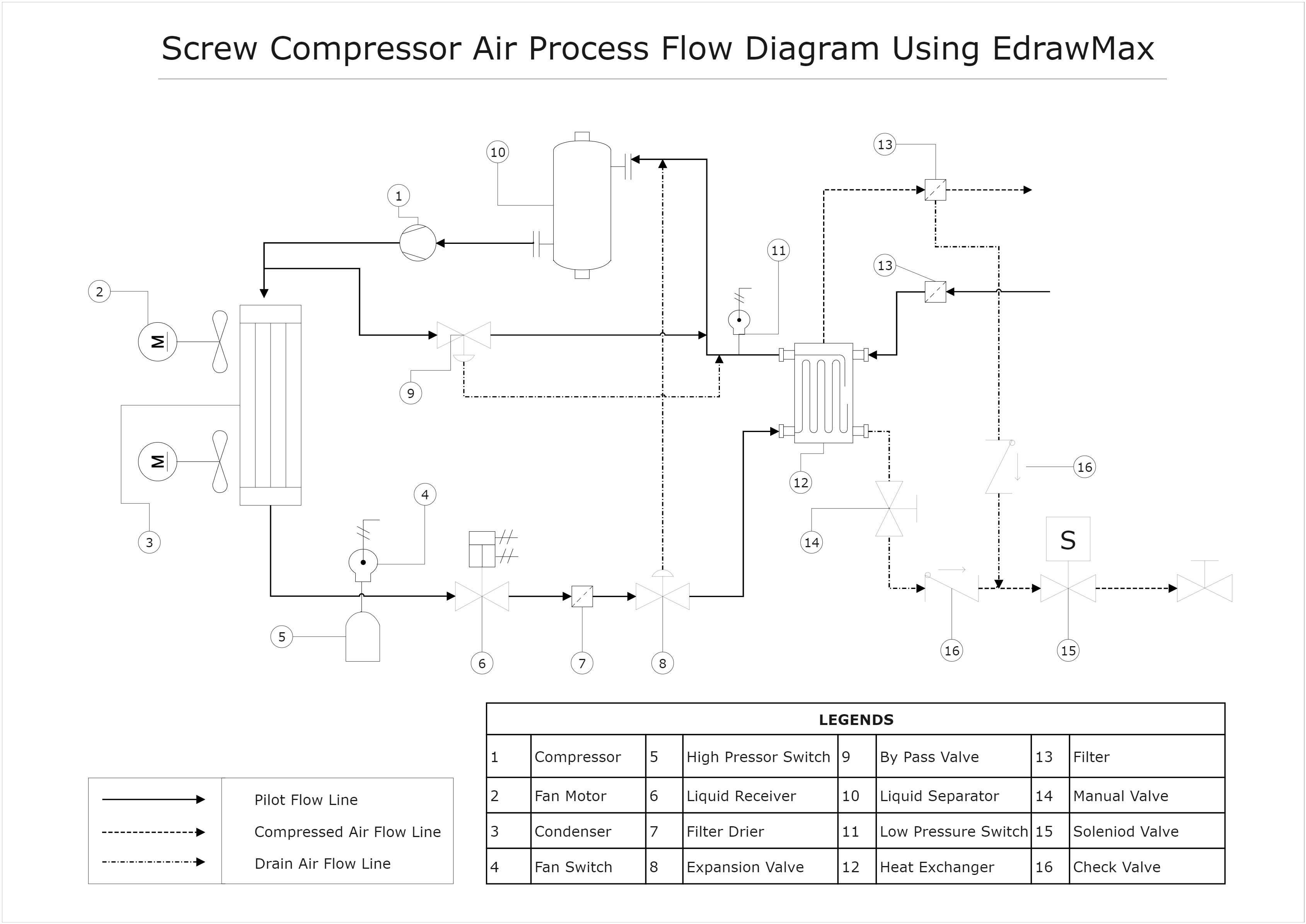

Screw Compressor Air Flow diagram

Screw Compressor Air Flow diagram

Zunair

Published on 2022-02-01

Here is the process flow diagram of Screw Compressor for air pattern flow and oil flow with in the compressor unit.

Watch the full video on Youtube FODIC. The basic idea of a screw compressor is that air is drawn in between the male and female rotors as they rotate in opposing directions. As the air passes between the rotors, it is compressed as the volume gap between them shrinks, resulting in compressed air that is displaced to the exit. The rotors' speed is set to a specific level to reduce mechanical losses (due to heat at high speeds) and volumetric losses (air losses due to very low speed). Unlike a piston compressor, a screw compressor often lacks valves and has no mechanical force that creates imbalance, allowing it to operate at high speeds while maintaining control over massive flow rates.

Tag

Compressor Process Flow diagram

IT

P&ID

Symbol

workflow diagram

Share

Report

7

1.0k

Post

Recommended Templates

Loading