Templates Community /

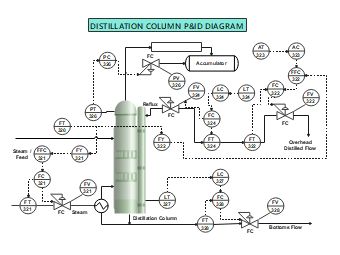

Distillation Column PID Diagram

Distillation Column PID Diagram

Ahmad Nadeem

Published on 2024-05-10

This figure is a process flow diagram of a fractional distillation column. Fractional Distillation is a separation process used to separate a mixture of two or more volatile liquids with respect to their boiling points. The diagram shows the feed as the raw material entering in the distillation column. At the top of the column there exists a condenser and at the bottom of the column there is a re-heater/boiler. The condenser works as a cooler in the column and the re-boiler as it names suggests works as a reheater. The final distilled product exits the condenser and the bottom product exits at the reboiler.

The text labels in the diagram refers to the following instruments:

FT (Flow Transmitter): Continuously measures the rate of fluid passing through a pipe.

FC (Flow Controller): Regulates the flow rate of a fluid by opening or closing a valve.

LT (Level Transmitter): Monitors the level of liquid in a tank or vessel.

LC (Level Controller): Maintains a desired liquid level in a tank by adjusting a pump or valve.

FV (Flow Valve): A valve controlled by a signal to regulate fluid flow.

PT (Pressure Transmitter): Continuously measures the pressure of a gas or liquid.

PC (Pressure Controller): Maintains a desired pressure in a system by adjusting a valve or pump.

DT (Differential Pressure Transmitter): Measures the difference in pressure between two points.

AT (Analyzer Transmitter): Continuously measures a specific property of a fluid, like its chemical composition.

AC (Analyzer Controller): Adjusts a process based on the output signal from an analyzer.

Tag

Chemical Engineering

IT

PID

Piping

P

Share

Report

12

1.6k

Post