What is Total Quality Management (TQM)

Create a TQM Online Free Free Download Free Download Free Download Free DownloadWhat is Total Quality Management (TQM)?

Total Quality Management is an updated version of the management concept, where the focus is on customer satisfaction. Quality is an aspect that defines whether a product or service is valuable, harmful, or useful. Thus, it determines the overall success of the business, especially in long term prospects.

In the practice of Total Quality Management, a continuous effort is to eliminate the errors in Manufacturing, streamline the process of supply chain management, ensuring employees’ improvement with training, and improving the overall customer experience. Although the concept looks somewhat similar to Six Sigma, it has differences. William Deming, a management consultant whose work impacts the Japanese Manufacturing a lot introduced TQM.

Image Source: ourmediatraining.com

History of Total Quality Management

The evolution of Total Quality Management definition dates back to the 1920s when it first came as scientific management principles through the U.S. industry. In the late 1920s, the Hawthorne Experiments showed how the productivity of workers impacted. At the same time, Inspection can be seen as very active right from the 1900s when the publication, 'The Principles of Scientific Management' was written by Frederick W. Taylor, the Father of Scientific Management.

Then, in the 1950s, some renowned publications were evident of the fact. Some of them include the book, 'Total Quality Control' by Armand V. Feigenbaum, the teaching of concepts of quality control by Joseph M. Juran. Moreover, the promotion of zero effects by Philip B. Crosby leads the way of quality improvement in many companies.

In 1968, the philosophy synthesis by Kaoru Ishikawa had contributed to the ascendancy of Japan as a quality leader. And today, TQM has developed as a well-structured philosophy to manage the overall organizational quality constraints.

Why is Total Quality Management Important?

TQM can have a positive impact on both organizations as well as employees. By having the core aim of total quality management, companies can uphold cultural values and establish a long-term achievement for both customers and organizations. See the purpose of TQM below.

- The purpose of TQM is to focus on continuous improvement through an approach like that of kaizen.

- To build the long-term success of an organization in terms of employees, customers, and clients.

- Quality improves, which is a superpower to maintaining long term and efficient success of an organization.

- Most importantly, customer satisfaction reaches by adopting the approach of TQM.

- The purpose is to gain a substantial edge over the competitors.

Benefits of Total Quality Management

Given below are the main benefits of using TQM.

-

Ensures production of superior quality products and services

You can measure a product’s quality in terms of reliability, performance, and durability. Thus, quality is an important parameter to differentiate an organization from its competitors. Superior product or service quality means satisfied customers, which is the main aim of TQM.

-

Fewer defects in products

A TQM approach helps to eliminate errors in products or services by making them superior. These errorless products also lead to customer loyalty. One of the main principles of TQM is to create the right products for the first time. Reduction in defects means a decrease in product fixes, product recalls, and future customer support.

-

Lower costs

As a result of positive improvements in product development, companies save considerable costs in field service, product replacements, customer support, and creating product fixes.

On the other hand, it ensures increased productivity and revenues for the organization because employees will earn if the organization is making money.

-

Well-defined values of culture

Organizations practicing TQM nurture core values with continuous improvement. This mindset presents across all aspects of an organization ranging from hiring to internal structure to product development. Thus, an organization will always remain in defined cultural values and provides only valuable services.

-

Helps to reduce inventory and waste

TQM helps to reduce inventory and waste while working closely with suppliers and incorporating the 'Just in Time' philosophy. It also ensures near coordination between employees of an organization. This aspect also inculcates the intense feeling of teamwork among workers.

Total Quality Management Principles

The TQM has evolved from distinct methodologies despite specific challenges to standardization. Well, it follows elementary principles.

-

Customer Satisfaction

It’s the core principle of TQM. Quality Management follows all the steps and measurements required for improving the quality of a product or service. It is because excellent quality only ensures customer satisfaction as well as customer retention for an extended period.

-

Employee Commitment

Not only consumer satisfaction and product improvement, but a sense of employee commitment are also essential for TQM. There are proper suggestion mechanisms and training for the purpose. Every employee is responsible for quality management. Both in terms of its improvement as well as improvement in production services.

-

Effective Communications

Open dialogue is TQM. Effective communication helps to resolve the issues much faster. Various suggestions can also be regulated quickly when one employee can easily communicate with another employee. Not only the employees, but a hierarchy also maintained from the top to a low level.

-

Factual Decision Making

All decisions made are on proper facts and data collection. Teams collect process statistics and data to ensure that desired work meets all the necessary specifications. This factual decision-making aspect further improves transparency in an organization.

-

Strategic Thinking

Strategic thinking helps improve the overall structure of an enterprise. All processes are well analyzed and structured in the alignment of long term vision. Things are categorized to think about the overall improvement of quality in all aspects.

-

Process-Centered

Every activity is deconstructed into processes and locates and repeat the best method possible. If we think logically, then it's the processes that pose the main problems rather than the people. Managers focus on processes when something undesirable happens. In this way, Total Quality Management positively is a process-centered approach.

-

Integrated System

This system further helps to keep everyone interconnected. A shared vision, including the commitment and knowledge to principles, creates an integrated system in an organization.

The Seven Basic Tools of Total Quality Management

Experts stress upon seven necessary tools of TQM as follows.

-

Pareto Chart

The chart indicates that 80% of problems are due to 20% of causes, which further helps to determine problems in different categories.

-

Check Sheet

It’s a kind of pre-made sheet to gather data and used for frequently recurring data.

-

Ishikawa Diagram or Cause and Effect Diagram

This diagram determines all possible causes for a problem and then categorize them.

-

Control Chart

It is a graphical chart to describe how results and processes change over time.

-

Scatter Diagram

Data plotted on both x and y-axis to see how results improve as a result of a change in variables.

-

Histogram Bar Chart

The frequency for a cause of the problem is shown here, along with the differences in the results cluster.

-

Stratification or Flow Chart Diagram

This diagram shows how various factors join a process.

Total Quality Management Examples

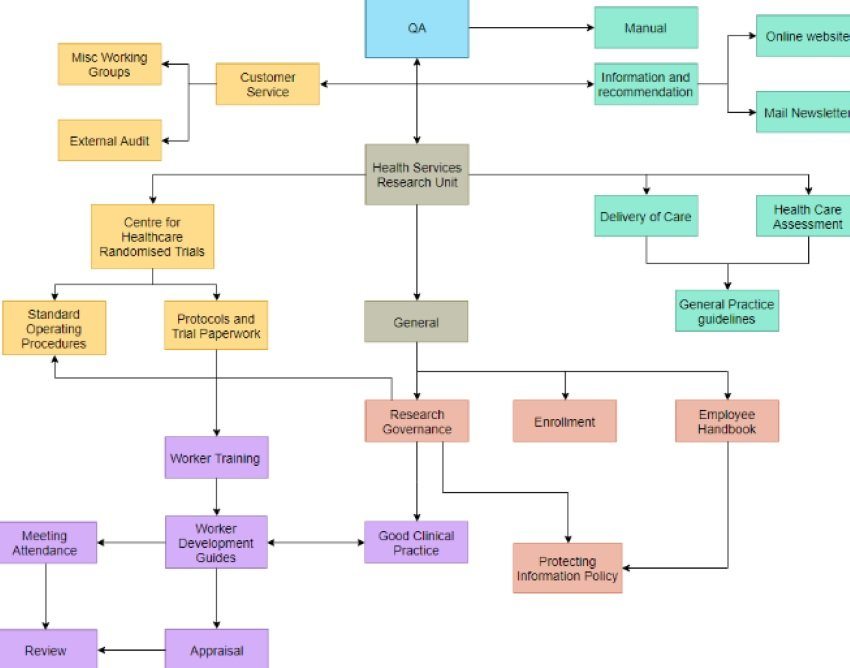

TQM is responsible for the overall development of healthcare organizations while creating a higher efficiency, reducing costs, and providing quality health care products to the patients.

Image Source: visual-paradigm.com

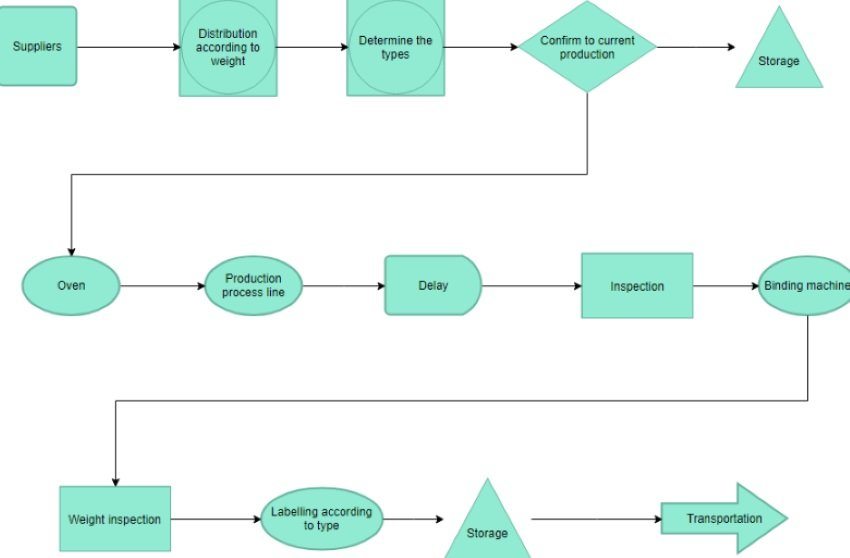

The factory is one of the critical places to implement TQM. It is used to increase productivity and reduce costs involved in handling inventory and various other non-operational tasks.

Image Source: visual-paradigm.com

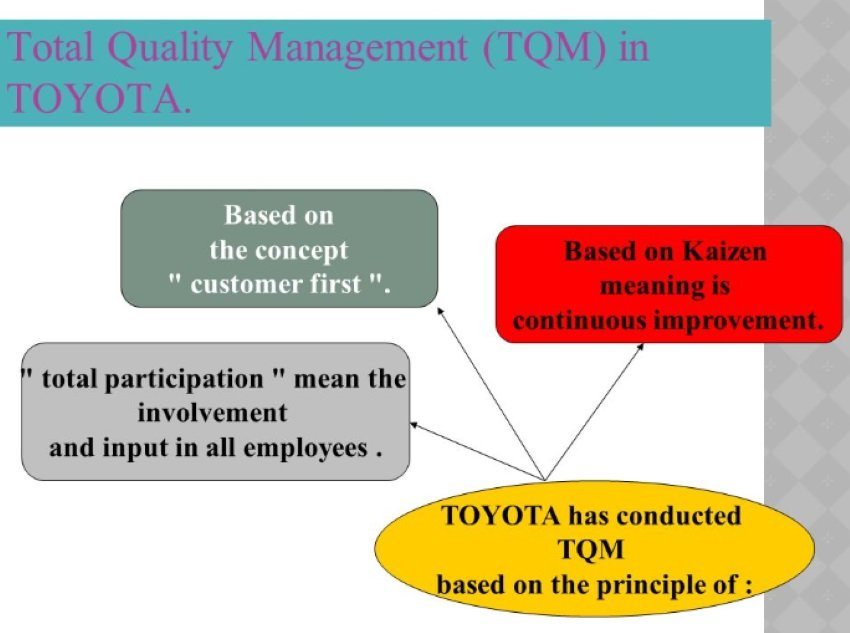

A company called Toyota has successfully implemented the concept of Total Quality Management to improve its quality circles. Following their approach, many automotive companies also initiated the process.

Image Source: slideplayer.com

How to Implement TQM with EdrawMax?

You can now use EdrawMax Online to create quality diagrams. It uses ready-made templates that you can customize as per your needs. Some models are also available in the free version.

You can now use EdrawMax Online to create quality diagrams. It uses ready-made templates that you can customize as per your needs. Some models are also available in the free version.

Things to know before creating a TQM diagram

You should follow the PDCA approach to create a TQM diagram. This PDCA refers to Plan, Do, Check, and Act.

-

Plan

Firstly, you should consider what needs addressing.

-

Do

You need to develop strategies and ask your employees to further improve or implement the necessary solutions in their processes.

-

Check

Check before as well as after the implementation of the plan.

-

Act

You need to let everybody know about your acts and executions for effective communication.

Go to the official website of EdrawMax Online and create an account. You can use the online version freely for up to three projects. On the other hand, the premium version of EdrawMax offers many more templates.

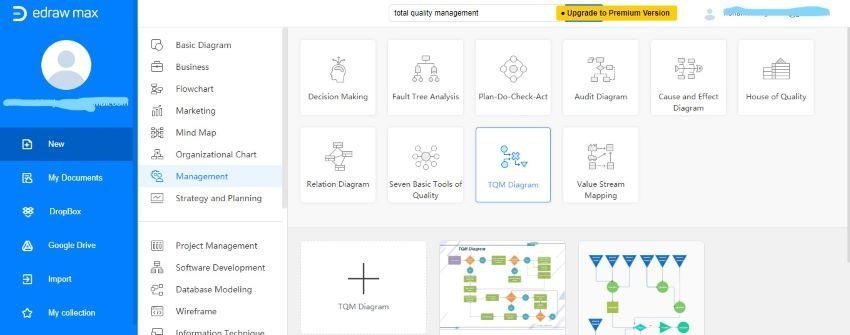

Write the TQM Diagram in the search tab or click Management. Various Management tools will open from where you have to select a TQM Diagram.

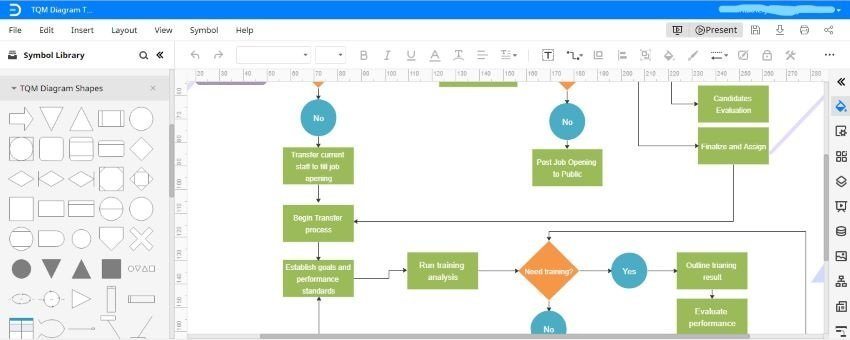

As you click the TQM Diagram, a new interface for the drawing will open. You can edit the template presented and select from various shapes and symbols provided in the side menu bar.

Limitatioons of Total Quality Management

Here are some of the limitations of TQM that you need to keep in mind:

- The requirement for company-wide commitment for quality improvement.

- Managers must be active onboard.

- Training programs need proper evaluation and implementation.